Introduction

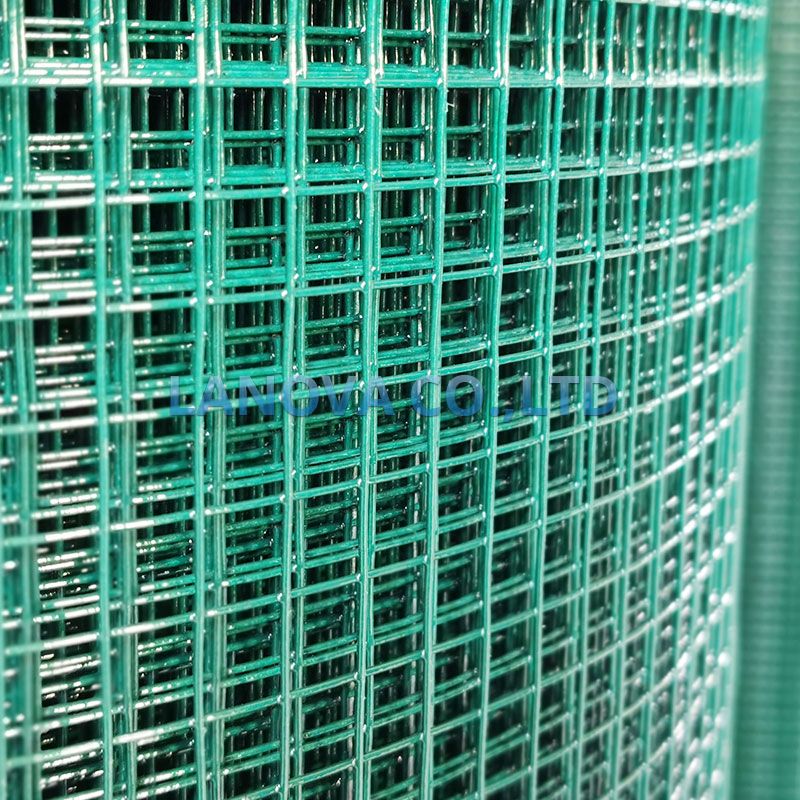

Welded mesh, also known as welded wire mesh or welded wire fabric, is a versatile and widely used material made by welding together intersecting wires at right angles. This mesh is commonly employed in various industries and applications due to its numerous advantages. In this article, we will explore the key benefits of welded mesh and why it is a preferred choice in construction, agriculture, fencing, and more.

Structural Integrity and Durability

One of the primary advantages of welded mesh is its exceptional structural integrity and durability. The welding process creates strong and stable connections between wires, ensuring that the mesh retains its shape and strength even under heavy loads or extreme environmental conditions. This makes it an ideal choice for applications that require long-lasting and robust materials, such as concrete reinforcement in construction projects.

Uniform Mesh Openings

Welded mesh offers uniform mesh openings, ensuring consistent spacing between wires throughout the entire sheet. This uniformity is crucial in various applications, such as concrete reinforcement and fencing, as it provides precise spacing and alignment. It also enhances the aesthetic appeal of the finished product.

Ease of Installation

Welded mesh is relatively easy to install due to its flat and flexible nature. It can be cut to the desired size and shape, making it adaptable to a wide range of applications. Whether you're reinforcing concrete, building cages for animals, or creating partitions, welded mesh simplifies the installation process, saving both time and labor costs.

Versatility in Applications

The versatility of welded mesh is one of its standout features. It finds applications in diverse industries, including:

Construction: Welded wire mesh is commonly used to reinforce concrete structures like walls, floors, and foundations. It enhances the structural integrity of these elements and reduces the risk of cracking and damage.

Agriculture: It is used for creating animal enclosures, poultry cages, and tree guards. The mesh provides protection while allowing air and light to pass through.

Security Fencing: Welded mesh is a popular choice for security fencing due to its strength and durability. It is effective at deterring intruders and maintaining perimeter security.

Gardening and Landscaping: Gardeners and landscapers use welded mesh for trellises, plant supports, and decorative features. It provides stability and support to climbing plants and structures.

Industrial and Manufacturing: In industrial settings, welded mesh is employed for machine guards, safety enclosures, and conveyor belt systems.

Cost-Effectiveness

Welded mesh offers excellent value for money. Its durability and low maintenance requirements mean that it can provide long-term cost savings. With minimal upkeep, it can last for many years without the need for replacements, reducing overall expenses.

High Strength-to-Weight Ratio

Despite its lightweight nature, welded mesh boasts a high strength-to-weight ratio. This property is particularly valuable in applications where weight considerations are crucial, such as in aerospace or automotive manufacturing. It can reduce the overall weight of structures and products without compromising strength.

Conclusion

Welded mesh's advantages, including durability, uniformity, ease of installation, versatility, cost-effectiveness, and high strength-to-weight ratio, make it a preferred choice in numerous industries and applications. Whether you're reinforcing concrete, securing a property, or supporting plants in your garden, welded mesh fence offers the reliability and versatility needed to get the job done efficiently and effectively. Its enduring popularity is a testament to its enduring utility in an array of fields.

Comments

0